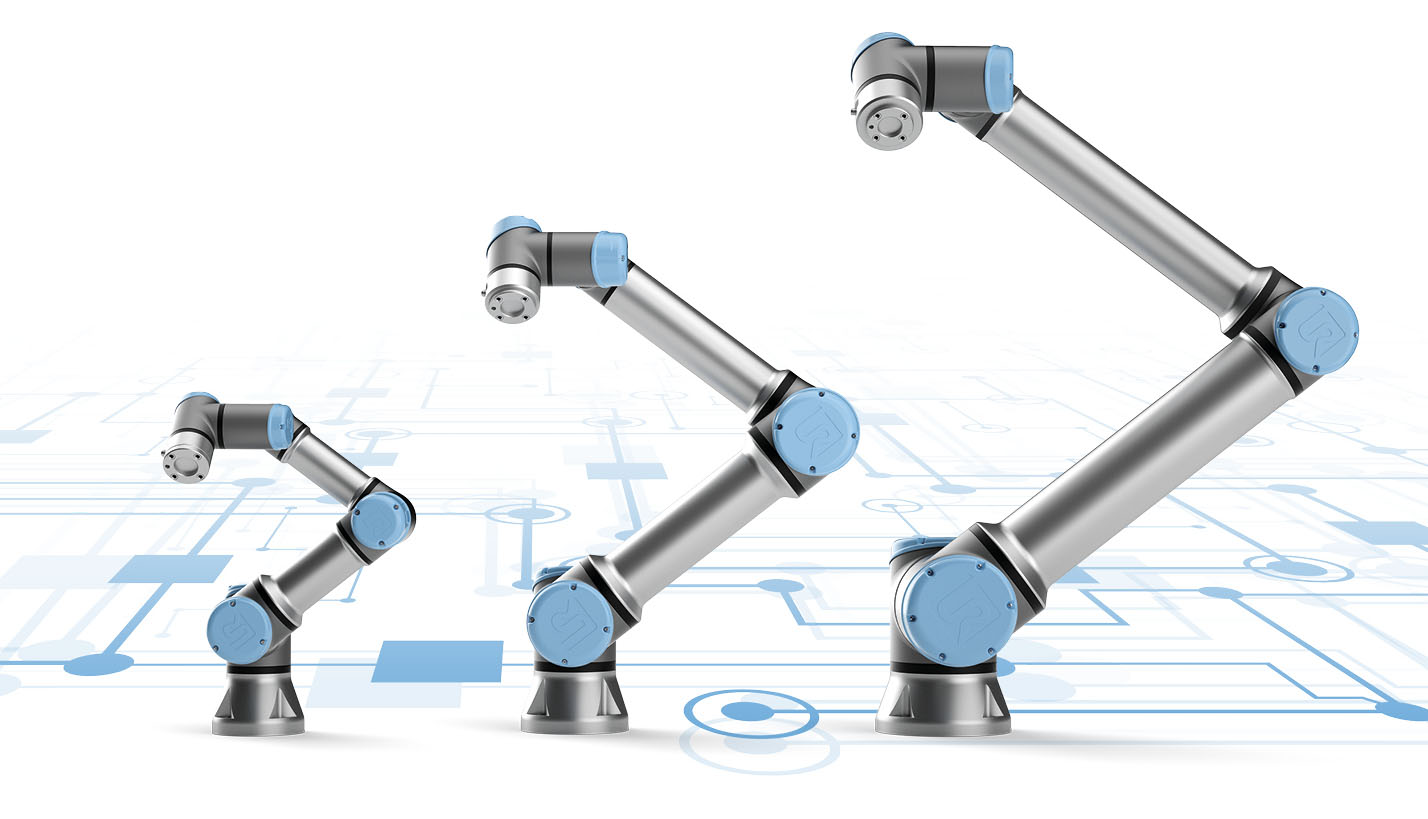

Universal Robots is continuing to evolve its ground-breaking, collaborative automation technology with the introduction of its new flagship e-Series cobots. The new range follows Universal Robot’s co-founder, Esben Østergaard being awarded the 2018 Engleberger Award, the ‘Nobel Prize’ of robotics.

This new e-Series cobot platform includes technology advances that enable faster development for a wider variety of applications. Improvements include the ability to economically address even more applications, thanks to greater precision and sensitivity provided by a built-in, tool-centric Force/Torque sensor.

The new e-Series offers unparalleled convenience, here are some of its features:

- It takes just one hour to unpack the cobot, mount it and program the first task.

- A wrist-join-tool communication interface reduces production line integration time and complexity with all joints can be replaced in 2 to 6 minutes.

- A re-designed intuitive and responsive-touch user interface expedites program development via a new lightweight, wide-screen Teach Pendant.

- 17 safety functions, including customisable stopping time and distance, make collaborative automation easier.

- Certified by TÜV Nord all these functions are in compliance with the EN ISO 13849-1 and EN ISO 10218-1 (Cat. 3 PLd) machinery safety standards for unobstructed human-robot collaboration.

Looking at the big picture, e-Series users can expect a fast return on investment, a cobot system ready for any future application, and long-term productivity gains.

Growing Importance of Automation in The Philippines

Demand for automation and robotics continues to grow in the Philippines, particularly in the automotive, electronics and food & beverage industries.

Electronics is among the top export sectors in the Philippines, contributing USD 8.69 billion in the first quarter of 2018 and a high adopter of cobots.

The Philippines’ Department of Trade and Industry (DTI) recognises the importance of electronics and the manufacturing sector and, in line with Industry 4.0, has introduced the Inclusive Innovation Industrial Strategy or i3S to sustain the sector’s robust growth. i3S includes training and upscaling of skills, developing or adapting available technologies and improving operational efficiency to meet global demands and opportunities.

This is timely as the Philippines was ranked among the lowest in the region by the International Federation of Robotics for automation adoption with a robot density of three industrial robots installed per 10,000 employees in 2016, behind Singapore, Thailand and Malaysia.

![]()